Decoding the Anatomy of a Meat Grinder: Essential Part Names and Functions

Understanding the specific names and functions of meat grinder part names is crucial for proper operation, maintenance, and replacement. Whether you own a compact electric model or a heavy-duty commercial meat mincer, the core mechanism remains consistent. This comprehensive guide breaks down every component, from the feeding tray to the locking ring, ensuring you can confidently identify, troubleshoot, and care for your equipment in 2025.

The Core Grinding Mechanism: Components of the Head Assembly

The grinding head, often referred to as the cylinder or throat, is where the raw material transformation occurs. These parts must be kept sharp, clean, and properly lubricated to ensure safe and efficient processing.

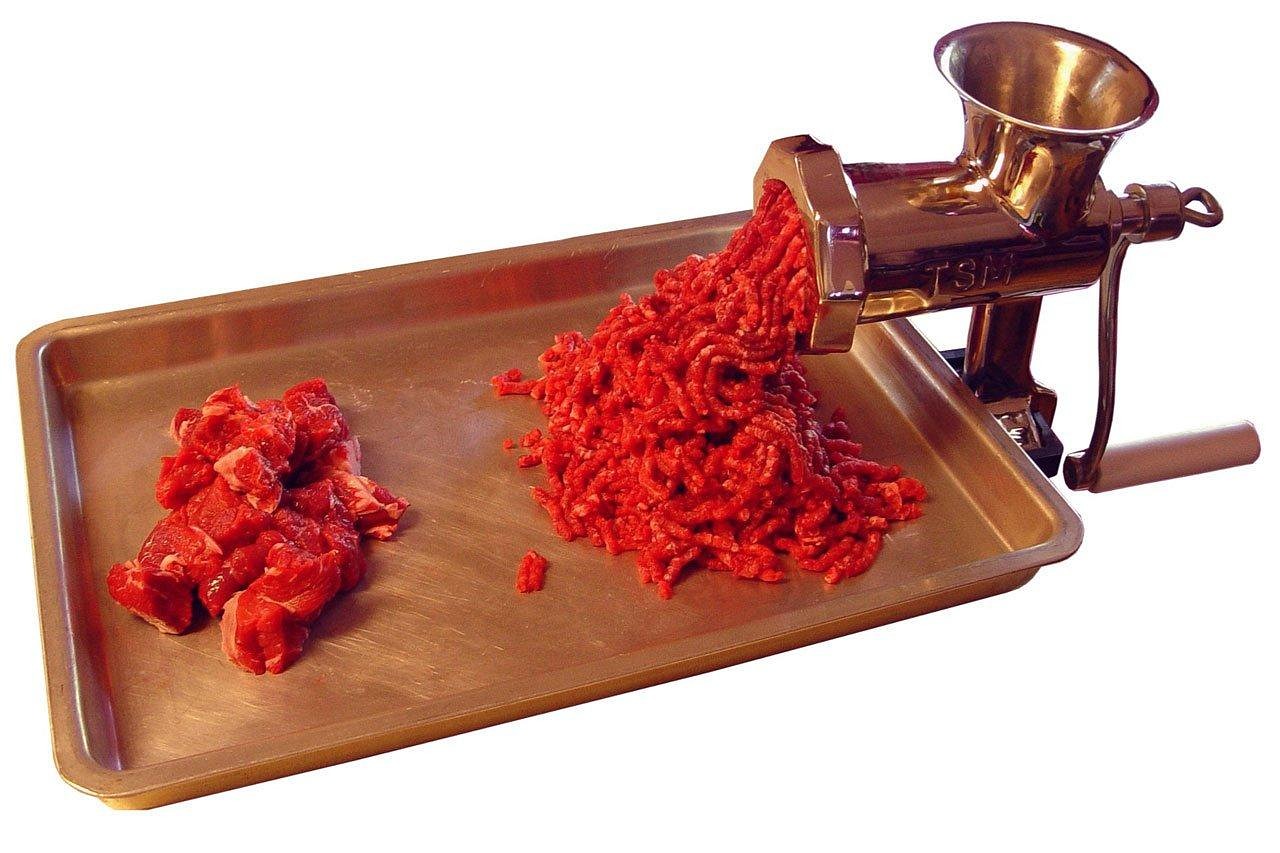

1. The Hopper (Feeding Tray)

Function: The hopper, or feeding tray, is the wide, shallow basin situated atop the grinding head. Its primary purpose is to hold the pre-cut meat before it is fed into the auger. The design allows for safe, hands-free staging of ingredients, minimizing the risk of contamination and ensuring a steady supply to the grinding mechanism.

Key Considerations: Hoppers are typically made of stainless steel or durable plastic. For commercial meat grinder machine parts names, the hopper size is often proportional to the grinder’s capacity, measured in pounds per hour (PPH).

2. The Grinding Head (Cylinder or Throat)

Function: The grinding head is the main housing that attaches to the motor unit (in electric models) or the main body (in manual models). It contains the auger, knife, and plate. Its internal structure is precisely machined to guide the meat from the hopper to the cutting elements.

Nomenclature Note: This component is sometimes simply called the ‘housing’ or ‘barrel.’ Its size dictates the overall capacity of the machine, corresponding to standard sizes like #8, #12, or #22.

3. The Auger (Worm)

Function: The auger, often called the ‘worm’ due to its helical screw shape, is the engine of the grinding process. It fits snugly inside the grinding head. As the motor rotates the auger, it draws the meat from the hopper, compresses it, and forces it forward against the stationary grinding knife and plate.

Maintenance Insight: The auger’s fit within the cylinder is critical. Excessive wear can lead to ‘smearing’ the meat rather than cleanly cutting it, resulting in poor texture and potential bacterial growth due to friction heat. Proper lubrication with food-grade oil is essential before storage.

4. The Grinding Knife (Blade)

Function: The grinding knife is a four-bladed cross-shaped component that rotates with the auger. It is the primary cutting element. It works in conjunction with the stationary grinding plate, shearing the meat as it is forced through the plate’s holes. The knife must be installed correctly, facing the plate, to ensure optimal performance.

Criticality: A dull or improperly installed knife is the most common cause of grinding failure. We recommend regular sharpening or replacement to maintain the integrity of the meat product. Learn more about meat grinder plate sizes and sharpening.

5. The Grinding Plate (Die)

Function: The grinding plate, or die, is a circular disc with precisely sized holes. It determines the final texture and coarseness of the ground meat. Plates come in various sizes, ranging from coarse (e.g., 10mm or 3/8 inch) for chili or sausage filling, to fine (e.g., 3mm or 1/8 inch) for pâtés or emulsified sausages.

Compatibility: Plates must match the specific size standard of the grinding head (#8 plate for a #8 grinder). Using the correct sequence of plates (coarse grind first, then fine grind) is a fundamental technique for achieving superior texture.

6. The Locking Ring (Cap)

Function: The locking ring, or cap, screws onto the end of the grinding head, holding the grinding plate and the knife securely in place against the auger. It applies the necessary pressure to ensure the knife and plate surfaces remain flush, which is vital for a clean cut.

Safety Note: The locking ring must be tightened firmly, but not excessively, to prevent damage to the threads or the components inside. Loose rings can cause the knife to wobble, leading to poor grinding quality.

Power and Structure: Parts of an Electric Meat Grinder Machine

Electric meat grinder parts names include the mechanical and electrical components that drive the grinding mechanism. These parts are responsible for the machine’s power, durability, and safety.

1. The Motor Housing and Chassis

Function: This is the external shell that protects the internal motor and gearbox. It provides stability and often includes ventilation slots to prevent overheating. The housing material (usually stainless steel, aluminum, or heavy-duty plastic) dictates the machine’s longevity and ease of cleaning.

2. The Motor and Gearbox Assembly

Function: The motor provides the rotational power, while the gearbox reduces the high speed of the motor to the lower, high-torque speed required to turn the auger. The quality of the gearbox—often featuring metal gears in commercial units—is the primary determinant of the grinder’s durability and ability to process tough cuts of meat or bone (for raw dog food preparation).

Torque vs. Speed: High-quality electric meat grinder parts list specifications will emphasize torque (measured in watts or horsepower) over simple speed, as torque is necessary to prevent stalling when grinding sinewy or frozen meat.

3. The Drive Shaft and Coupling

Function: The drive shaft connects the gearbox output to the auger. The coupling is a mechanism, often plastic or metal, designed to absorb shock and sometimes act as a sacrificial fuse. If the grinder jams severely (e.g., hitting a piece of metal), the coupling is designed to break, protecting the more expensive motor and gearbox from damage.

4. The Pusher (Stomper)

Function: The pusher, or stomper, is a safety tool used to guide meat down the throat of the grinding head. It ensures that the operator’s hands never come close to the moving auger. It is an indispensable safety component and should always be used when feeding meat.

5. Control Panel and Safety Features

Function: This includes the power switch, reverse function, and circuit breaker. The reverse function is critical for clearing jams without disassembling the unit. Modern grinders often include thermal protection, which automatically shuts off the motor if it begins to overheat.

Manual Meat Mincer Parts: Simplicity and Durability

Manual meat mincer parts name lists are much shorter, reflecting their robust, non-electric design. These antique-style grinders are prized for their simplicity and lack of reliance on electricity.

1. The Clamp or Suction Base

Function: This component secures the manual grinder firmly to a countertop or table edge. Traditional models use a screw-down clamp, while modern versions may utilize a powerful suction base for easier setup and removal.

2. The Crank Handle

Function: The crank handle is attached to the drive shaft of the auger. Turning the handle manually provides the power to process the meat. The length of the handle often provides leverage, making the grinding process easier.

3. The Screw/Wingnut Mechanism

Function: In manual models, a large screw or wingnut is often used to secure the grinding head to the main body, replacing the complex coupling system found in electric units.

Specialized Accessories and Attachments

Modern meat grinders are versatile tools, often equipped with specialized attachments that expand their functionality beyond simple grinding. These accessories are crucial for tasks like sausage making and vegetable processing.

1. Sausage Stuffer Tubes and Funnels

Function: These attachments replace the knife and plate assembly. The auger forces the ground meat (or sausage mix) through a funnel-shaped tube, which guides the mixture directly into natural or synthetic casings. Different tube diameters are used for various sausage types, such as breakfast links or large Italian sausages. For more on this functionality, review our guide on the best meat grinder sausage stuffer combos.

2. Kubbe/Kibbeh Attachments

Function: Kubbe attachments are specialized nozzles used to form hollow tubes of meat dough, which are then stuffed and sealed to create the traditional Middle Eastern dish, kibbeh. This requires a very fine grind and precise extrusion.

3. Shredder and Slicer Drums

Function: While the core function is grinding, many electric models include accessory drums for processing vegetables, cheese, or nuts. These drums feature various cutting or grating surfaces and address the common confusion between meat slicer parts names and meat grinder accessories. A meat slicer uses a large rotating blade for thin, uniform cuts of cooked meat, while these grinder attachments use rotating drums for shredding or grating.

Maintenance and Compatibility: Understanding Part Sizes and Materials

Proper care and understanding of part compatibility are essential for maximizing the lifespan and performance of your meat grinder.

Grinder Size Standards (Entity Norms)

Meat grinders adhere to industry-standard sizes, which are critical when purchasing replacement meat grinder parts names like plates, knives, or augers. The size designation (e.g., #5, #8, #12, #22, #32) refers to the diameter of the grinding plate and the size of the grinding head opening. A #8 grinder requires #8 plates and knives, ensuring a perfect fit and safe operation.

| Grinder Size | Plate Diameter (Approx.) | Typical Use Case |

|---|---|---|

| #5 | 2.1 inches (53 mm) | Small, home use |

| #8 | 2.5 inches (63 mm) | Standard home/light commercial |

| #12 | 2.75 inches (70 mm) | Medium commercial/butchery |

| #22 | 3.25 inches (83 mm) | Heavy commercial/industrial |

Material Considerations and Sanitation

The materials used for the components directly impact food safety and durability. Stainless steel is the preferred material for all food-contact surfaces (auger, knife, plate, head) due to its resistance to rust, ease of sanitation, and non-reactive properties. Cast iron, while durable, requires meticulous cleaning and seasoning to prevent rust, especially in meat mincer parts name components of older manual models.

Regular cleaning, immediately after use, is paramount. Disassembling the unit completely and washing all components with hot, soapy water, followed by thorough drying, prevents bacterial growth and corrosion. For detailed instructions, consult our guide on meat grinder care and maintenance.

Proper Assembly Sequence

Correct assembly is vital for performance. The sequence is always: Grinding Head -> Auger -> Knife (blades facing out) -> Plate -> Locking Ring. Misalignment, particularly of the knife and plate, will result in poor grinding and potential damage to the components.

Frequently Asked Questions (FAQ)

What is the difference between an auger and a worm gear in a meat grinder?

In the context of meat grinding, the terms ‘auger’ and ‘worm’ are often used interchangeably to describe the helical screw component that pushes the meat. However, technically, the ‘worm gear’ refers to the gear mechanism inside the gearbox that transfers power from the motor shaft to the auger shaft, while the ‘auger’ is the component that handles the meat.

How do I know when to replace the grinding knife or plate?

Grinding knives and plates should be replaced when the edges become rounded or pitted, or when you notice the grinder is ‘smearing’ the meat rather than cutting it cleanly. A simple test is to check if the knife and plate surfaces are perfectly flat and mate seamlessly. If light passes between them when held together, they need replacement or professional sharpening.

Are electric meat grinder parts interchangeable between different brands?

Generally, no. While the size standards (#8, #12, etc.) define the plate and knife diameter, the specific coupling mechanisms, auger lengths, and locking ring threads vary significantly between manufacturers. Always purchase replacement electric meat grinder parts list items specifically designed for your machine’s brand and model number.

Why does my meat grinder have a reverse function?

The reverse function is a crucial safety and maintenance feature. If sinew, bone fragments, or tough connective tissue cause a jam, running the auger in reverse can often clear the blockage without requiring immediate disassembly, protecting the motor and gearbox from excessive strain.

What is the purpose of the plastic coupling or drive gear?

In many electric grinders, the coupling that connects the motor to the auger is intentionally made of a softer material (often plastic or nylon). This component acts as a shear pin or fuse. If the auger encounters an obstruction that could damage the motor (like a large bone or metal), the coupling breaks first, saving the much more expensive motor and gearbox assembly.

Ensuring Longevity: Next Steps for Part Replacement and Care

Maintaining a detailed understanding of meat grinder part names empowers you to perform necessary repairs and upgrades, ensuring your equipment delivers consistent, high-quality results for years to come. Whether you are replacing a worn knife or upgrading to a larger plate size, always prioritize genuine, high-quality stainless steel components that match your grinder’s size standard.

To maximize the performance and lifespan of your machine, commit to immediate post-use cleaning and ensure all cutting surfaces are kept sharp. If you are considering an upgrade or need to source specific replacement parts, consult reputable suppliers who specialize in commercial-grade equipment and parts.

References

- National Sanitation Foundation (NSF). NSF/ANSI 8: Commercial Food Preparation and Processing Equipment. 2025. — This standard outlines the minimum food protection and sanitation requirements for commercial meat processing equipment, including material safety and cleanability.

- Journal of Food Engineering. Optimizing Screw Conveyor Design for Viscoelastic Food Products: Torque, Shear Rate, and Temperature Control. 2025. — This academic article details the mechanical engineering principles behind auger (screw conveyor) design, focusing on how geometry affects torque requirements and minimizes heat generation during meat grinding.

- Meat Processing Industry Association. Best Practices for Meat Grinder Maintenance and Component Sourcing. 2025. — This industry guide provides practical advice on identifying wear patterns in grinding knives and plates, and outlines the standardized sizing conventions (#8, #12, etc.) used across the global meat processing sector.

Last Updated on October 14, 2025 by Robert Vance