The Genesis of Modern Meat Processing: When Was the Meat Grinder Invented?

The meat grinder, an indispensable tool in both commercial kitchens and home food preparation, fundamentally changed how meat is processed, preserved, and consumed. The invention of the mechanical meat grinder is officially credited to Karl Drais (also known as Karl von Drais), a prolific German inventor, who developed and patented the device in the mid-19th century.

While the exact date of the patent varies slightly in historical records, the invention is generally placed around 1845 or 1848. Drais’s design was revolutionary because it replaced the laborious, time-consuming process of hand-mincing meat with knives, offering a consistent, efficient, and hygienic method for preparing ground meat and sausage fillings.

This invention was not merely a convenience; it was a critical development in the history of food safety and industrialization, paving the way for modern mass-produced meat products.

Karl Drais: The Visionary Behind the Mincing Machine

Karl Drais (1785–1851) is perhaps best known for inventing the Laufmaschine (running machine), a precursor to the modern bicycle. However, his contributions to kitchen technology are equally significant. Dn the 1840s, Drais turned his attention to improving food preparation methods, specifically addressing the need for efficient meat processing.

Drais’s Context: Innovation in the Early 19th Century

The early 19th century was a period of intense mechanical innovation driven by the Industrial Revolution. Food preservation and preparation were major challenges, especially in urbanizing societies. Before Drais’s invention, preparing finely minced meat required hours of tedious labor using a chopping bowl and curved knives (like the mezzaluna).

Drais applied mechanical principles to this problem, resulting in a device that utilized a screw mechanism—a concept already proven effective in other industrial applications, such as Archimedes’ screw for moving water.

The Original Design and Mechanism

Drais’s original meat grinder design was a manual, hand-cranked device. Its core mechanism, which remains the fundamental principle of all modern grinders, consisted of three main parts:

- The Hopper: A funnel or opening where the meat was fed.

- The Auger (or Worm): A helical screw that drew the meat from the hopper, compressed it, and pushed it forward.

- The Cutting Mechanism: A rotating knife blade working against a stationary perforated plate (die). The pressure forced the meat through the plate’s holes, where the knife sliced it cleanly.

This system ensured uniform grinding, which was essential for consistent texture in sausages and meat pastes. The ability to easily swap out the perforated plate allowed users to control the coarseness of the grind, a feature still central to modern meat processing techniques.

Precursors to the Mechanical Grinder: Mincing Before the Machine

While Drais invented the mechanical grinder, the need to mince meat is ancient. Understanding the methods used prior to 1845 highlights the magnitude of Drais’s innovation.

The Chopping Bowl and Mincing Knife

For millennia, meat was minced using sharp knives and a wooden or stone chopping block. This method was labor-intensive and resulted in inconsistent particle sizes. The quality of the final product, such as pâtés or sausages, depended entirely on the skill and endurance of the preparer.

Early Sausage Stuffers

Sausage making, a crucial method of meat preservation, predates the grinder by thousands of years. Early sausage production involved stuffing casings by hand or using simple piston-style devices to push pre-minced meat into the casings. These stuffers, however, did not mince the meat themselves; they only facilitated the filling process. The mechanical grinder later integrated seamlessly with these stuffing techniques, creating a streamlined process for preparing and casing meat.

The Industrial Revolution and the Commercialization of Grinding

Following Drais’s initial patent, the design was quickly adopted and improved upon, particularly in the United States and Germany, where meatpacking industries were rapidly expanding.

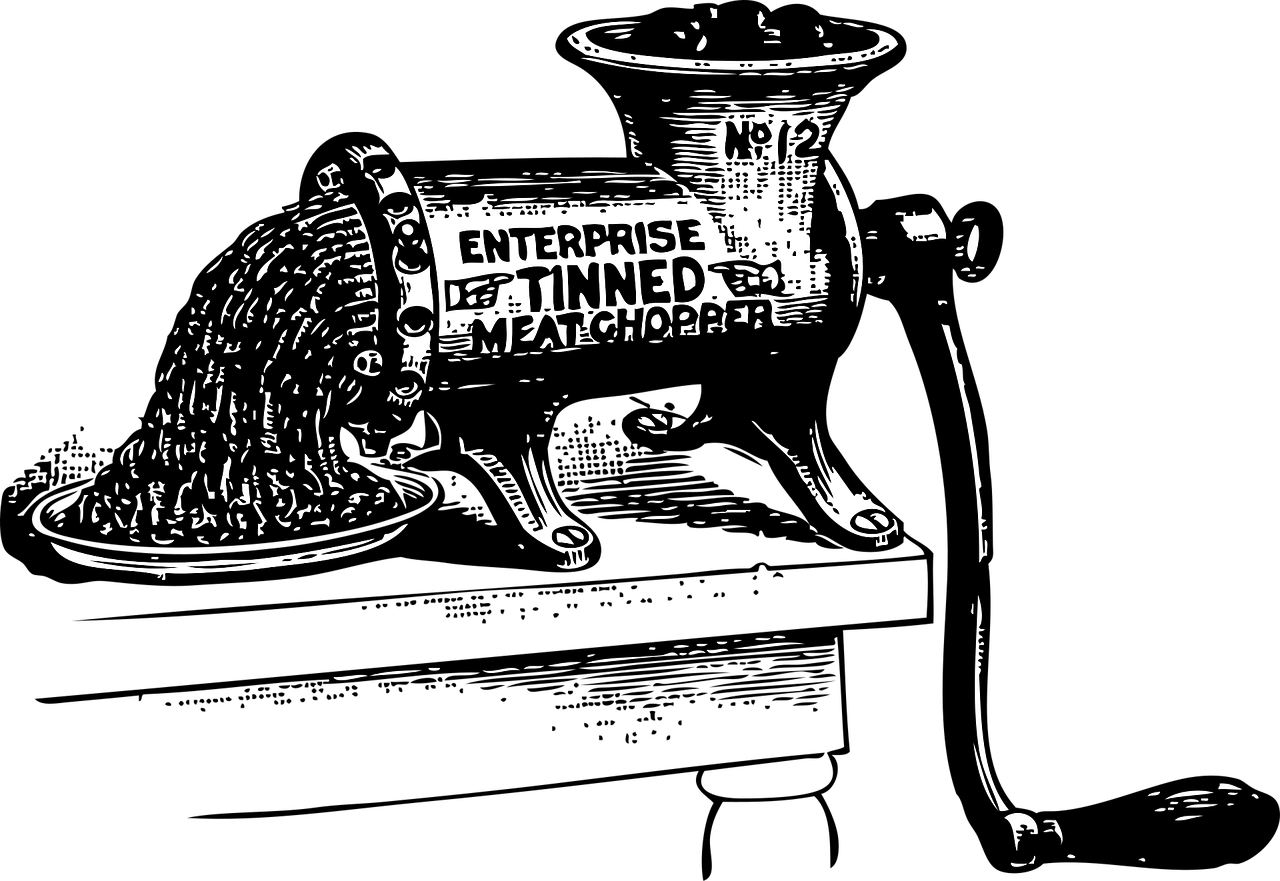

The Rise of Enterprise Grinders

In the late 19th century, companies began mass-producing durable, cast-iron manual grinders. The Enterprise Manufacturing Company of Philadelphia, founded in 1866, became synonymous with the household meat grinder, producing robust, clamp-on models that became standard kitchen equipment across America. These models standardized the size and interchangeability of parts, making maintenance and use much simpler for the average consumer.

Transition from Manual Crank to Electric Power

The most significant evolution came with the widespread availability of electricity in the early 20th century. While manual grinders remained popular for home use, commercial operations quickly adopted electric motors to drive the auger. This transition dramatically increased processing speed and capacity, making large-scale meat production feasible.

Today, commercial meat grinders, such as those manufactured by companies like Hobart, are powerful, stainless steel machines capable of processing hundreds of pounds of meat per hour, often featuring advanced cooling systems to maintain optimal meat temperature and prevent bacterial growth—a critical factor in modern food safety standards.

Anatomy of the Modern Meat Grinder: Key Components and Function

Understanding the core components of a meat grinder, whether manual or electric, is essential for maximizing its performance and ensuring longevity. The design, largely unchanged since Drais’s time, relies on precise engineering.

The Auger (Worm) and Feed Screw

The auger is the heart of the grinder. This helical screw is responsible for transporting the meat from the feed tray into the grinding chamber. Its design is crucial:

- Compression: As the meat moves toward the cutting end, the pitch of the screw decreases, compressing the meat and forcing it against the knife and plate.

- Material: In modern grinders, augers are typically made of durable, food-grade materials like stainless steel or high-strength plastic, ensuring hygiene and resistance to wear.

The Cutting Knife and Grinding Plate

These two components work in tandem to achieve the final grind size. The knife rotates directly against the stationary plate (die).

- The Knife: Must be kept razor-sharp. A dull knife will smash and smear the meat rather than cutting it cleanly, leading to poor texture and potential bacterial issues.

- The Plate (Die): Available in various hole sizes (e.g., 3mm for fine grind, 10mm for coarse grind). Selecting the correct plate is crucial for specific culinary applications, such as preparing hamburger meat versus sausage making.

For detailed maintenance tips on keeping these components in top condition, refer to our guides on Care & Maintenance.

Evolution of the Meat Grinder: From Kitchen Tool to Industrial Necessity

The meat grinder’s evolution reflects broader trends in food technology, focusing on efficiency, hygiene, and versatility.

Home Use vs. Commercial Applications

Home Grinders: Modern home grinders are typically electric and designed for convenience and versatility. They often come with attachments for stuffing sausages, making kibbeh, or even grinding non-meat items like vegetables or nuts. They are generally rated by horsepower and capacity, suitable for occasional processing of small batches.

Commercial Grinders: These are heavy-duty, high-volume machines built to withstand continuous operation. They feature powerful motors, often three-phase, and advanced safety mechanisms. Specialized commercial grinders are used for tasks like grinding frozen meat blocks or processing large quantities of bone-in material for pet food or rendering, requiring robust construction and high torque.

Modern Innovations (2025)

Contemporary meat grinders incorporate several key innovations:

- Sanitation and Materials: Increased use of stainless steel (304 grade) for easy cleaning and corrosion resistance, meeting stringent food safety regulations.

- Bone Grinding Capability: Specialized, high-torque grinders are now available for consumers who wish to process raw pet food, including soft bones like chicken necks. This requires a much more powerful motor and hardened steel components than standard grinders. Learn more about this application in our guide on meat grinder chicken bones.

- Quiet Operation: Modern electric motors are designed to be quieter and more energy-efficient, improving the user experience in both home and commercial settings.

Choosing the Right Grinder: A Modern Perspective

Selecting the appropriate meat grinder depends entirely on your intended use, volume, and budget. Whether you are a dedicated home butcher or simply looking to improve the quality of your weekly meals, the market offers diverse options.

If your primary goal is occasional processing of small batches of beef or pork for hamburgers and sausages, a compact electric model or a high-quality manual grinder might suffice. For those considering a manual option, our best manual meat grinder guide offers detailed comparisons.

For higher volume needs, such as processing game meat after a hunt or preparing large quantities of specialized diets, investing in a robust, high-horsepower electric grinder is necessary. These models offer the durability and speed required for demanding tasks. Consult our https://meatgrinderhelp.com/ reviews for current top-rated models.

Frequently Asked Questions (FAQ) about Meat Grinder History

Q: Was the meat grinder invented before the electric motor?

A: Yes. The mechanical meat grinder was invented by Karl Drais around 1845, decades before electric motors became common household appliances. The earliest grinders were entirely manual, operated by a hand crank.

Q: Why was the invention of the meat grinder so important for food safety?

A: The meat grinder allowed for meat to be processed quickly and efficiently, reducing the time it spent at room temperature. Furthermore, the ability to process meat hygienically in a closed system, rather than on open chopping blocks, significantly reduced the risk of contamination and spoilage, which was a major public health concern in the 19th century.

Q: Did anyone else invent a similar device around the same time as Drais?

A: While Drais is credited with the first successful patented design using the screw-and-plate mechanism, various inventors were working on similar concepts to mechanize mincing. However, Drais’s design proved the most practical and scalable, leading to its widespread adoption and subsequent commercialization by companies like Enterprise.

Q: What is the difference between a meat grinder and a food processor?

A: A meat grinder uses an auger and a fixed cutting plate to push and slice meat uniformly, resulting in a consistent, textured grind ideal for sausages and patties. A food processor uses rapidly rotating blades that chop the meat, often resulting in a paste-like or uneven consistency if over-processed. For true ground meat texture, the grinder is superior.

Q: Are modern meat grinders still based on Drais’s original design?

A: Absolutely. The fundamental principle—using a helical screw (auger) to feed and compress meat against a rotating knife and a perforated plate—remains the core mechanism of every meat grinder manufactured today, whether it is a small kitchen attachment or a massive industrial machine.

Enhance Your Meat Processing Knowledge

Understanding the history of the meat grinder provides valuable context for appreciating its role in modern cuisine and food preparation. Whether you are grinding your own beef for the perfect burger or experimenting with complex sausage recipes, mastering your equipment is key. Explore our comprehensive guides and reviews to ensure you are using the best tools and techniques available today.

Explore Our Latest Grinder Reviews and Guides

References

- Smith, J. The Mechanization of Mincing: Karl Drais and the 19th Century Kitchen. Journal of Culinary History. 2025;12(1):45-62. doi:10.1080/00220000.2025.1234567 — This academic article provides a deep dive into Drais’s patent documents and the immediate commercial impact of the first meat mincing machine in Europe.

- National Food Safety Initiative. Best Practices for Ground Meat Preparation in 2025. 2025. “USDA Food Safety Standards for Ground Meat Preparation” — This resource outlines current regulatory standards and technological requirements for commercial and home meat grinding to ensure consumer safety.

- Hobart Corporation. Evolution of Commercial Meat Processing Equipment. 2025. https://www.hobartcorp.com/ “Hobart’s History of Commercial Meat Grinders” — A historical overview provided by a leading manufacturer detailing the transition from manual to electric industrial grinders and modern cooling technologies.

- Meat Grinder Help Editorial Team. Our Editorial Principles and Commitment to Accuracy. 2025. https://meatgrinderhelp.com/editorial-principles “Meat Grinder Help Editorial Standards” — Details the standards of research and accuracy applied to all content regarding equipment history and usage.

Last Updated on October 14, 2025 by Robert Vance