The Definitive Guide to Choosing the Best Manual Meat Grinder in 2025

For serious home cooks, hunters, and those prioritizing control over their food preparation, the manual meat grinder remains an indispensable kitchen tool. Unlike their electric counterparts, hand meat grinders offer superior control, durability, and reliability, particularly for processing small to medium batches of meat, poultry, or vegetables.

Choosing the right model requires understanding the core mechanics, material science, and capacity requirements. This comprehensive guide details the essential factors and top recommendations to help you find a reliable, high-performance manual meat grinder that will last for decades.

Why Choose a Hand Meat Grinder Over Electric Models?

While electric grinders offer speed, the manual model provides specific advantages that appeal to a dedicated user base. Understanding these benefits clarifies why a hand-cranked device is often the superior choice for quality and longevity.

Portability and Off-Grid Use

A manual meat grinder requires no electricity, making it ideal for use in remote cabins, during camping trips, or in kitchens with limited power outlets. Their simple, robust design means they are ready to operate anywhere, anytime, provided you have a stable surface to mount them.

Cost-Effectiveness and Longevity

Manual grinders, especially those made from high-quality materials like stainless steel or seasoned cast iron, contain fewer moving parts susceptible to electronic failure. This simplicity translates to a lower initial cost and a significantly longer lifespan, often requiring only replacement grinding plates or knives over time. They are true workhorses built for endurance.

Control Over Grind Consistency

Operating a manual grinder gives the user direct tactile feedback and control over the speed of the auger. This is crucial when processing delicate meats or when aiming for a specific texture, such as a coarse grind for chili or a fine emulsion for pâté. The slower, deliberate rotation minimizes heat generation, which is vital for maintaining the quality and safety of the meat by preventing fat smearing.

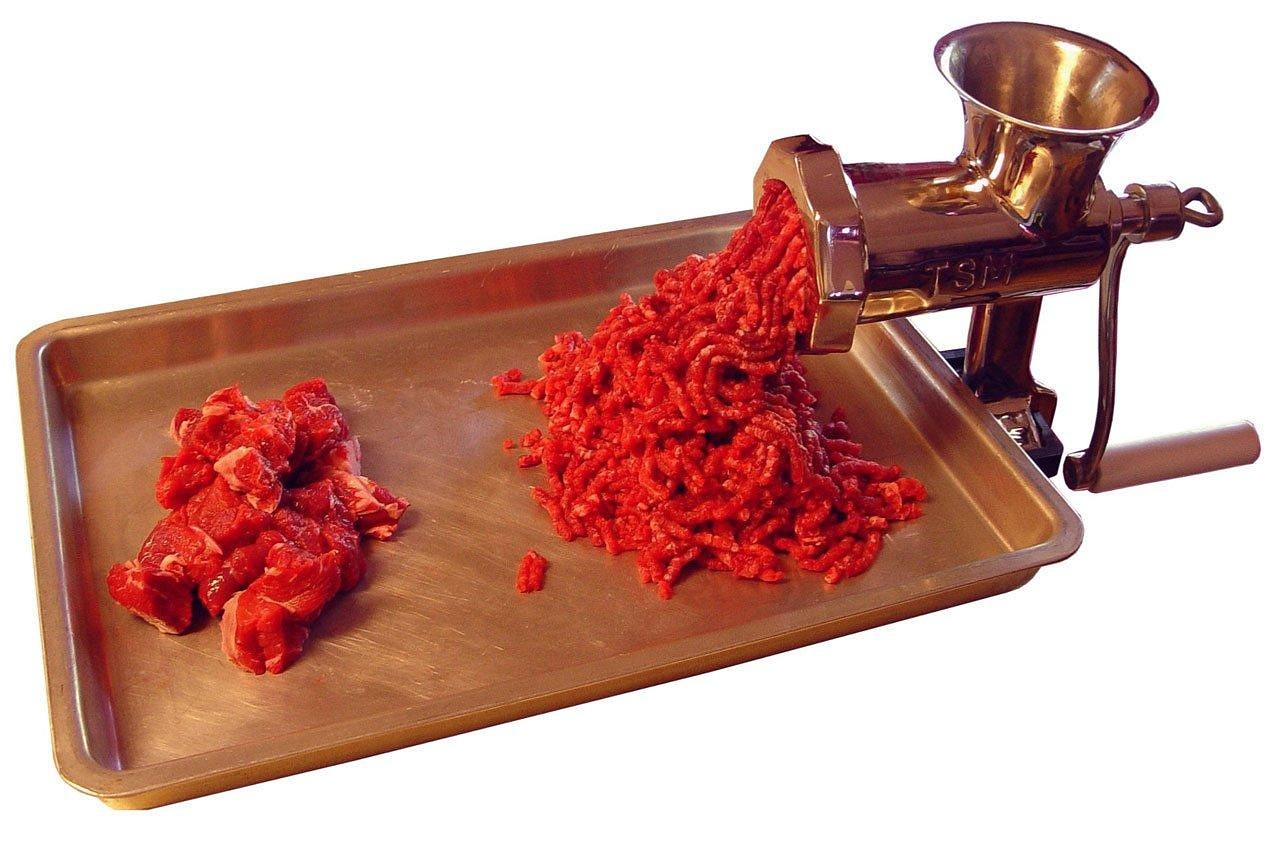

Critical Components and Anatomy of a Manual Meat Grinder

To select the best manual meat grinder, it is essential to understand the function of its primary components. These entities work in concert to transform whole cuts into ground product.

The Hopper and Feed Tube

This is the opening where the meat is placed. A wider hopper allows for larger pieces of meat, reducing the need for extensive pre-cutting. The feed tube guides the meat toward the auger.

The Auger (Worm)

The auger is the helical screw that draws the meat from the hopper toward the cutting mechanism. The efficiency and design of the auger are critical for smooth operation. A well-designed auger minimizes resistance, making the cranking process easier.

The Knife and Plate System (Grinding Plates)

The knife rotates against the stationary grinding plate, shearing the meat as it is forced through the plate’s holes. Grinding plates come in various sizes (e.g., coarse 10mm, medium 4.5mm, fine 3mm) and are interchangeable, allowing the user to dictate the final texture of the product. High-quality knives and plates are made from hardened steel to maintain a sharp edge.

The Crank Handle and Clamp/Base Mechanism

The handle provides the leverage necessary to turn the auger. The mounting mechanism—either a heavy-duty clamp or a powerful suction base—ensures the grinder remains stable during strenuous operation. For heavy-duty use, a robust clamp that secures firmly to a thick countertop is preferred.

Key Factors for Selecting the Right Manual Meat Grinder

When evaluating models, focus on these material and structural attributes to ensure you purchase a device suited to your processing needs.

Material Science: Cast Iron vs. Stainless Steel

| Feature | Cast Iron (Tinned/Coated) | Stainless Steel (Food Grade 304) |

|---|---|---|

| Durability | Extremely heavy-duty; virtually indestructible. | Highly durable and resistant to corrosion. |

| Maintenance | Requires careful cleaning, drying, and seasoning to prevent rust. | Dishwasher safe (for most models); easy to clean and sanitize. |

| Weight | Very heavy, providing excellent stability. | Lighter than cast iron, but still substantial. |

| Cost | Generally lower initial cost. | Higher initial investment, but lower long-term maintenance effort. |

| Food Safety | Must be properly tinned or seasoned to prevent metal contact with food. | Non-reactive and inherently food-safe, meeting strict standards. |

For maximum hygiene and minimal maintenance, stainless steel is often the preferred choice, especially when processing large volumes or for commercial applications. However, a well-maintained, tinned cast iron grinder offers unmatched stability and grinding power.

Size and Capacity: Understanding Grinder Numbers

Manual meat grinders are categorized by size, which corresponds to the diameter of the grinding plate and the overall capacity of the machine. Choosing the correct size is crucial for efficiency:

- #5 and #8: Compact, ideal for small batches, occasional use, or grinding nuts and vegetables. Suitable for apartment kitchens.

- #10 and #12: The standard size for serious home processing. These offer a good balance of capacity and manageable cranking effort.

- #22 and #32: Large, commercial-grade sizes. These are typically used by hunters or those processing whole animals, requiring significant counter space and robust mounting.

If you plan to process more than five pounds of meat at a time, selecting a #10 or #12 manual meat grinder will significantly reduce the time and effort required.

Mounting Mechanism: Clamp-Style vs. Suction Base

- Clamp-Style: Uses a screw mechanism to secure the grinder to the edge of a counter or table. This provides the most secure hold, essential when applying significant torque to grind tough or sinewy meat. Ensure your countertop edge is compatible (usually 1 to 2 inches thick).

- Suction Base: Relies on vacuum pressure to adhere to a smooth, non-porous surface. While convenient for quick setup, these can lose suction during heavy use, leading to instability. Best suited for light-duty tasks.

Top-Rated Manual Meat Grinders for Home Use (2025 Reviews)

Based on durability, ease of use, and material quality, these categories represent the best options available for the modern kitchen.

Best Overall Versatility: The Stainless Steel #10 Model

Stainless steel #10 grinders offer the perfect blend of capacity for home use and the hygienic benefits of non-reactive metal. They are typically easy to disassemble and clean, and the size handles most common grinding tasks, from beef for burgers to pork for sausage making. Look for models with precision-machined augers and hardened steel cutting blades.

Best for High Volume Processing: The #22 Cast Iron Workhorse

For users processing deer, elk, or large batches of poultry, the sheer size and weight of a #22 cast iron grinder provide the necessary stability and throughput. These require a dedicated, sturdy mounting location. When purchasing, verify that the cast iron has a durable, food-safe tin coating to prevent rust and direct contact with the iron.

Best Budget Option: Compact #5 Clamp Grinder

If your needs are limited to occasional grinding—perhaps making baby food, mincing garlic, or grinding small amounts of chicken—a compact #5 model is economical and requires minimal storage space. While slower than larger models, they are excellent entry points into manual meat processing.

Mastering the Manual Grinding Technique

Achieving a perfect grind requires more than just turning the crank; preparation and technique are paramount.

Preparing the Meat and Chill Factor

This is the most critical step. The meat and all grinder components (auger, knife, plates, hopper) must be kept extremely cold—ideally between 30°F and 32°F (-1°C to 0°C). Chilling the meat until it is firm (but not frozen solid) ensures clean cuts and prevents the fat from smearing, which results in a poor texture and can clog the grinder. Cut meat into strips or cubes that fit easily into the hopper without forcing.

The Double Grind Method

For very fine textures, or when incorporating spices and binders for sausage, the double grind method is recommended. First, use a coarse plate (e.g., 10mm) to break down the large chunks. After the first pass, chill the ground meat again, and then run it through a finer plate (e.g., 4.5mm or 3mm). This technique ensures uniform texture and better flavor distribution.

For more detailed instructions on achieving specific textures, consult our guides on Grinding Techniques.

Safety and Operational Best Practices

Always use the provided stomper or pusher to feed meat into the grinder. Never use fingers or utensils to push meat down the feed tube. Ensure the grinder is securely mounted before beginning operation to prevent accidents and damage to the equipment or countertop.

Essential Care and Maintenance for Longevity

Proper care ensures the longevity of your investment and, more importantly, guarantees food safety.

Proper Cleaning and Sanitization

Immediately after use, disassemble the manual meat grinder completely. Wash all parts in hot, soapy water. Use a brush to remove any residual meat or fat from the auger threads and plate holes. Rinse thoroughly. Sanitization is crucial, especially when processing raw meat. A diluted bleach solution or commercial sanitizer should be used according to food safety guidelines.

Seasoning and Preventing Rust (for Cast Iron models)

Cast iron grinders must be dried immediately after washing. Any moisture left on the surface will lead to rust. Once dry, apply a thin layer of food-grade mineral oil or vegetable shortening to all metal surfaces, including the interior of the hopper and the auger. This process, known as seasoning, creates a protective barrier against oxidation. If you are considering restoring an older model, our used hobart meat grinder guide offers detailed restoration tips.

For comprehensive instructions on maintaining your equipment, visit our Care & Maintenance section.

Frequently Asked Questions (FAQ) About Manual Meat Grinders

How do I sharpen the manual meat grinder knife and plate?

The knife and plate must be sharpened together to ensure they mate perfectly. This is typically done by rubbing them in a figure-eight motion on a flat sharpening stone (whetstone) or fine sandpaper placed on a glass surface. They must be perfectly flat and sharp to achieve a clean cut. If the knife is dull, the meat will be crushed rather than sliced.

Can I grind bones in a manual meat grinder?

No. Manual meat grinders are designed for soft tissues, sinew, and fat. Attempting to grind bones, even small poultry bones, will likely damage the knife, plate, and potentially crack the auger or housing. For bone grinding, specialized, high-powered electric grinders or dedicated bone crushers are required.

What is the difference between a meat grinder and a food mincer?

Historically, ‘mincer’ was the common term, particularly in British English, while ‘grinder’ is preferred in American English. Functionally, they refer to the same device: a machine that forces meat through a perforated plate using an auger and a rotating knife. The term ‘mincer’ is sometimes used for smaller, less robust manual models.

How much meat can a #12 manual grinder process per hour?

While highly dependent on the operator’s speed and the meat’s preparation, a skilled user can typically process between 5 to 10 pounds of properly chilled, pre-cut meat per hour using a #12 manual grinder. This rate is significantly slower than industrial electric models but provides superior texture control.

Why is my manual grinder pushing out mushy meat instead of ground meat?

Mushy meat is almost always a result of warm meat or dull blades. If the meat temperature rises above 40°F (4°C), the fat softens and smears, leading to a mushy texture. Ensure the meat and all components are thoroughly chilled, and check that the knife and plate are sharp and correctly installed (flat sides facing each other).

Take Control of Your Meat Processing

Investing in a quality manual meat grinder is a commitment to superior food quality and self-sufficiency. By selecting the correct size and material—whether the hygienic durability of stainless steel or the robust stability of cast iron—you ensure years of reliable service. Master the chilling and grinding techniques, and you will consistently produce ground meat that surpasses anything available commercially.

Start your journey toward better home processing today by exploring the range of high-capacity, durable hand grinders available from reputable suppliers.

References

- USDA Food Safety and Inspection Service. Meat and Poultry Processing Guidance. 2025. “USDA Guidelines for Safe Meat Processing” — This resource provides critical temperature and sanitation guidelines essential for safe home meat grinding.

- American Meat Science Association. The Science of Grinding: Temperature Control and Texture. 2025. https://www.meatscience.org/publications/fact-sheets/the-science-of-grinding “Meat Science Principles of Grinding” — This academic source details how temperature affects fat emulsification and the resulting texture of ground meat.

- National Sanitation Foundation (NSF). Standards for Food Processing Equipment. 2025. “NSF Standards for Grinder Materials” — This organization outlines the material requirements and hygienic design standards for food-contact equipment, emphasizing the benefits of food-grade stainless steel.

Last Updated on October 14, 2025 by Robert Vance