Preserving the Legacy: Understanding the Rival Meat Grinder

The Rival meat grinder holds a unique place in the history of home food processing equipment. While the brand, now part of the Newell Brands portfolio, has evolved significantly since its heyday, many vintage Rival units—both manual and electric—remain highly valued by home butchers and enthusiasts for their robust construction and reliability. This guide provides a comprehensive overview of the most popular Rival meat grinder models, essential maintenance procedures, and advice on sourcing critical replacement parts in { 2025 }.

Understanding the operational lifespan and specific requirements of these legacy machines is crucial for safe and effective use. Whether you are restoring a classic Model 303 or troubleshooting an electric Model 2300, specialized knowledge is required to keep these durable appliances running efficiently.

The History and Evolution of Rival Appliances

Rival Manufacturing Company, founded in the 1930s, became a household name synonymous with dependable kitchen appliances, including the iconic slow cooker. Their entry into the meat processing market provided consumers with accessible, durable tools for preparing ground meat and sausage at home. The longevity of these early units is a testament to their build quality, often featuring heavy-duty cast metal components rather than modern plastic assemblies.

However, the brand has changed hands multiple times, moving from Rival to Sunbeam, then Jarden Corporation, and finally becoming part of Newell Brands. This corporate evolution means that direct manufacturer support for older models, particularly those produced before the 1990s, is often unavailable. Users must rely on specialized third-party suppliers and community knowledge for meat grinder problems and maintenance.

Key Rival Meat Grinder Models and Specifications

Two models frequently appear in discussions among vintage appliance collectors and home processing enthusiasts: the Model 303 and the Model 2300.

Rival Meat Grinder Model 303

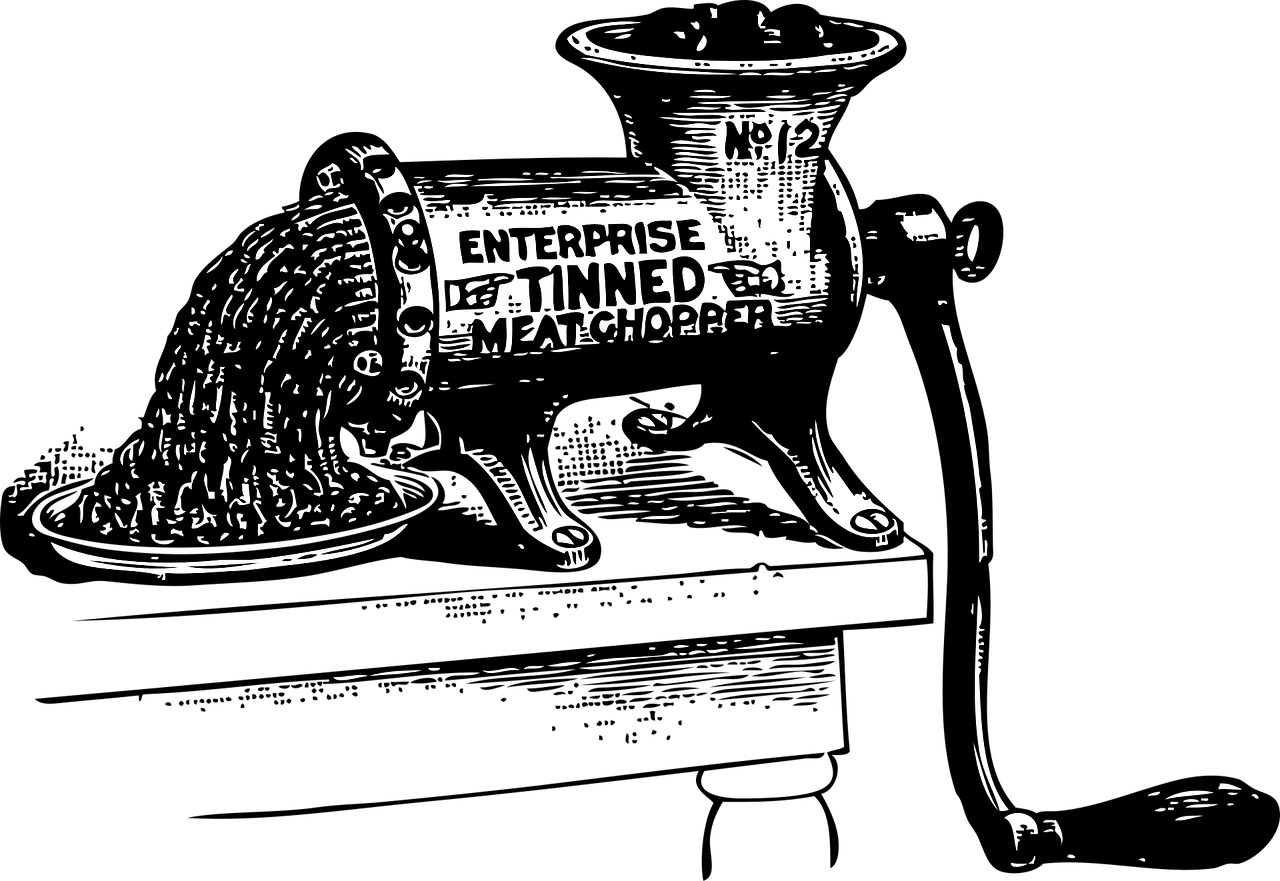

The Rival Model 303 is typically a manual, hand-cranked unit designed for durability and portability. It embodies the classic design of a clamp-on grinder, attaching securely to a countertop or table. This model is highly prized for its simplicity and the ability to process small batches of meat without relying on electricity.

Key Attributes of the Model 303:

- Operation: Manual, requiring physical effort but offering precise control over grinding speed.

- Construction: Often cast iron or heavy-duty aluminum, ensuring long-term structural integrity.

- Maintenance Focus: Requires regular cleaning, drying, and light lubrication (using food-grade mineral oil) to prevent rust, especially in the cast iron components.

- Parts Compatibility: Generally uses standard #5 or #8 size grinding plates and blades, though specific Rival parts may be required for the auger and locking ring.

Rival Meat Grinder Model 2300

The Rival Model 2300 is an electric meat grinder, representing a shift toward convenience and higher volume processing. This model typically features a powerful motor designed for home use, capable of handling larger quantities of meat for sausage making or preparing ground beef.

Key Attributes of the Model 2300:

- Operation: Electric motor-driven, significantly faster than manual models.

- Power: Often rated for medium-duty home use, suitable for occasional large batches.

- Troubleshooting: Common issues include motor overheating under heavy load and wear on the plastic gears (if present) or the coupling mechanism.

- Safety Features: Users must strictly adhere to duty cycles (run time limits) to prevent motor burnout, a common failure point in older electric grinders.

Essential Rival Meat Grinder Parts and Accessories

Maintaining a vintage Rival unit often hinges on the availability and condition of its internal components. Unlike modern appliances where the entire unit might be replaced, Rival owners frequently seek specific parts to extend the life of their machine.

The Critical Components

- The Auger (Worm Gear): This component feeds the meat toward the cutting blade and plate. Wear on the auger, particularly the drive end, can lead to inefficient grinding and slippage. For electric models, the connection point between the auger and the motor drive shaft is a common area of concern.

- The Blade (Knife): The blade must be razor-sharp to achieve a clean cut. A dull blade will smash and smear the meat, leading to poor texture and potential bacterial growth due to increased friction and temperature. Replacement blades for Rival units must match the specific model size (e.g., #5 or #8).

- Grinding Plates: These plates determine the final texture of the ground meat. Rival units typically came with coarse, medium, and fine plates. Over time, the holes can become slightly distorted or the plate surface pitted, requiring replacement for optimal performance.

- Stuffing Tubes and Attachments: Many Rival grinders included attachments for sausage making. Ensuring these tubes are clean and free of cracks is vital for sanitary sausage making.

Sourcing Replacement Components

Because Rival no longer actively manufactures these specific parts, sourcing requires diligence. Owners should look for reputable third-party suppliers specializing in vintage appliance parts or generic parts compatible with standard grinder sizes (#5, #8, #10). When searching for parts, always specify the model number (e.g., Rival meat grinder parts Model 303) to ensure proper fit and function.

Troubleshooting Common Rival Meat Grinder Problems

Operating older equipment comes with unique challenges. Addressing these issues proactively ensures both the longevity of the machine and the safety of the food being processed.

1. Motor Overheating (Electric Models)

Symptom: The motor slows down, emits a burning smell, or shuts off automatically.

Cause: Excessive load, prolonged use beyond the recommended duty cycle, or internal mechanical friction.

Solution: Always chill the meat thoroughly before grinding (ideally near freezing). Cut meat into strips that fit easily into the hopper. If the problem persists, the motor brushes or internal wiring may need professional inspection. Never attempt to bypass thermal safety switches.

2. Meat Smearing or Mushing

Symptom: The ground meat has a paste-like consistency rather than distinct strands.

Cause: Dull blade, incorrect assembly (blade facing backward), or meat temperature too high.

Solution: Sharpen or replace the blade. Ensure the blade is installed correctly, with the cutting edge facing outward against the plate. Always work with meat that is below 40°F (4°C). For guidance on preparation, consult a buying bulk meat guide.

3. Grinder Jams and Blockages

Symptom: The auger stops turning, or the machine struggles to push meat through.

Cause: Too much sinew, bone fragments, or feeding meat too quickly.

Solution: Stop the machine immediately. Disassemble the head and clear the obstruction. Ensure all meat is properly trimmed of excessive silver skin and bone before grinding. If using a manual grinder, apply steady, even pressure rather than sudden force.

Comprehensive Care and Maintenance for Longevity

Proper care is paramount for preserving the functionality and hygiene of a Rival meat grinder, especially vintage cast iron units susceptible to rust.

Disassembly and Cleaning Protocol

- Immediate Cleaning: Disassemble the grinder head immediately after use. Meat residue can dry quickly and harbor bacteria.

- Washing: Wash all metal components (auger, blade, plates, locking ring) by hand in hot, soapy water. Avoid using a dishwasher, as the harsh detergents and high heat can damage the metal finish, leading to corrosion.

- Drying: Thoroughly dry every component immediately after washing. Use a towel and then allow them to air dry completely for several hours.

- Lubrication: For cast iron parts, apply a thin layer of food-grade mineral oil to prevent rust during storage. This is a critical step for meat grinder restoration.

Storage Recommendations

Store the cleaned and oiled metal components wrapped in wax paper or a cloth inside a sealed container. This protects them from moisture and dust. Electric motors should be stored in a cool, dry place, away from extreme temperature fluctuations.

Finding the Rival Meat Grinder Manual

Locating the original Rival meat grinder manual for models like the 303 or 2300 can be challenging. These documents contain vital information regarding assembly, capacity, and specific maintenance instructions.

- Digital Archives: Many enthusiast forums and specialized appliance repair websites maintain digital archives of vintage manuals. Searching specifically for “Rival meat grinder manual Model 2300 PDF” often yields results.

- Third-Party Retailers: Some parts suppliers bundle digital copies of the manual with replacement parts purchases.

- General Guides: If the specific manual is unavailable, consult general guides for similar-sized grinders, focusing on the assembly sequence and cleaning protocols, which are often standardized across brands.

Frequently Asked Questions (FAQ) About Rival Grinders

Q: Are Rival meat grinders still manufactured?

A: The Rival brand is owned by Newell Brands, but the specific vintage models like the 303 and 2300 are no longer in production. Any new Rival-branded meat grinders sold today are modern appliances manufactured under license and bear little resemblance to the heavy-duty vintage units.

Q: Can I use my vintage Rival grinder for grinding bones?

A: No. Vintage Rival home meat grinders, whether manual or electric, are designed for processing soft tissues (meat and fat). Attempting to grind bones, even soft poultry bones, will severely damage the blade, plates, and potentially strip the gears or burn out the motor in electric models. For bone grinding, specialized, high-horsepower commercial grinders are required.

Q: How do I know if my Rival grinder uses a #5 or #8 plate?

A: The size (#5, #8, #12, etc.) refers to the diameter of the grinding plate and the corresponding head size. You can measure the diameter of the plate in inches and compare it to standard sizing charts (e.g., a #8 plate is typically about 2.5 inches in diameter). Always confirm the size before ordering rival meat grinder parts.

Q: What is the best way to sharpen the Rival meat grinder blade?

A: The blade must be sharpened flat against the plate surface to maintain the necessary shear action. Professional sharpening services can resurface the blade and plate simultaneously. Home users can use a fine sharpening stone or sandpaper placed on a perfectly flat surface (like glass) to hone the blade’s flat side, ensuring the cutting edge remains flush with the plate.

Q: Is it safe to buy a used Rival meat grinder?

A: Yes, provided you inspect it thoroughly. Check for rust, cracks in the housing, and excessive wear on the auger. For electric models, plug it in briefly to ensure the motor runs smoothly and quietly. Always sanitize the unit completely before its first use.

Get Started: Finding Your Next Grinder or Essential Parts

If you are looking to replace a worn-out Rival unit or are searching for a modern equivalent that matches the durability of these vintage machines, research is key. Consult a comprehensive buy meat grinder guide to compare capacity, horsepower, and material quality. For those committed to restoring their existing Rival unit, prioritize sourcing high-quality, stainless steel replacement blades and plates to maximize performance and food safety.

References

- National Center for Home Food Preservation. Safe Handling of Ground Meats. 2025. https://nchfp.uga.edu/ — This resource provides essential guidelines on maintaining safe temperatures and minimizing bacterial risk during the home grinding process.

- Appliance Repair Experts Association. Economics of Vintage Appliance Restoration: Motor Longevity and Component Sourcing. 2025. — This industry report analyzes the viability of repairing and maintaining older kitchen appliances, focusing on common failure points like motor assemblies and gear wear in legacy electric grinders.

- University of Wisconsin-Madison Extension. Best Practices for Home Sausage Making and Meat Preparation. 2025. https://fyi.extension.wisc.edu/safefood/sausage-making-guide — This academic guide details the proper techniques for trimming meat, controlling fat ratios, and utilizing grinding equipment to achieve optimal texture and safety in home meat processing projects.

Last Updated on October 14, 2025 by Robert Vance