The Authority in Home Processing: A Deep Dive into LEM Meat Grinders

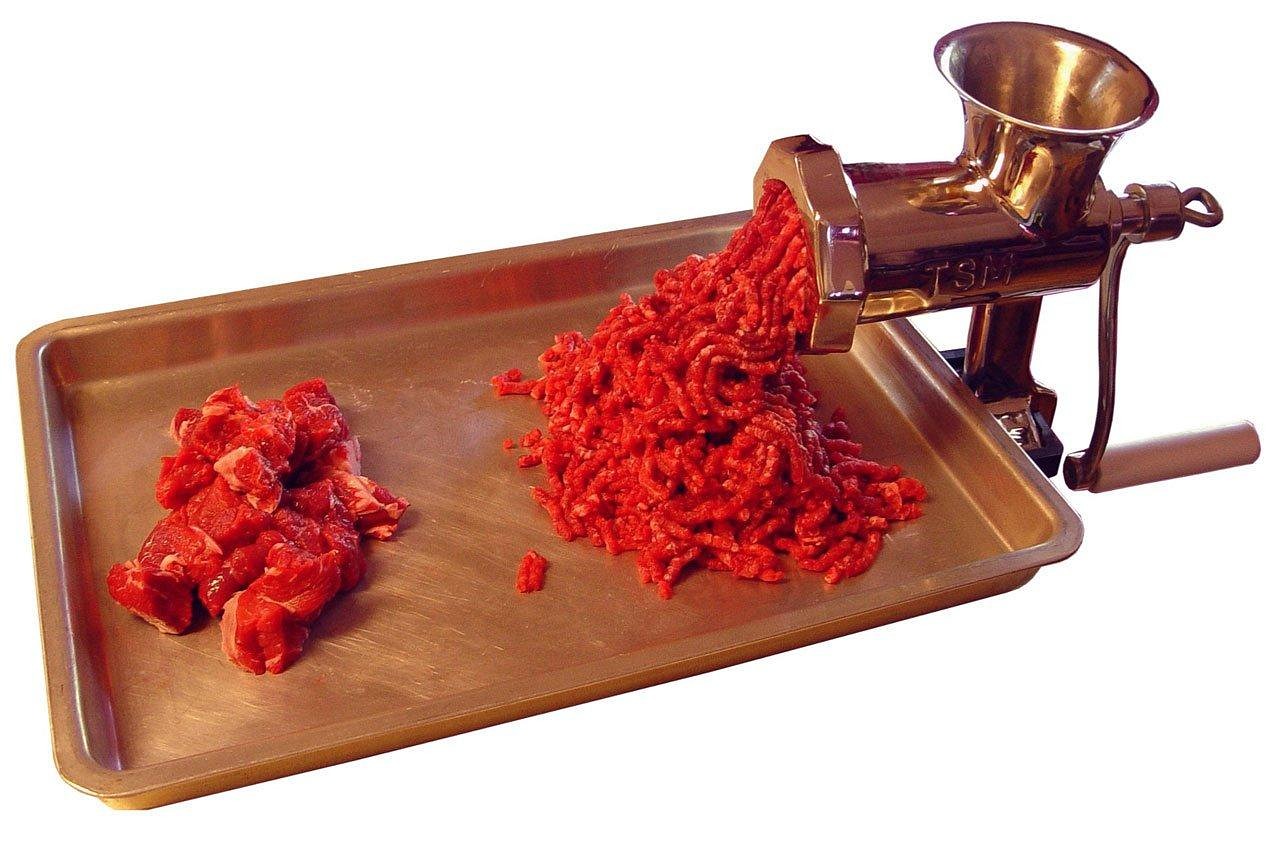

LEM Products has established itself as a cornerstone brand for serious home meat processors, hunters, and small-scale butchers. Unlike entry-level kitchen appliances, LEM grinders are engineered for capacity, durability, and continuous use, bridging the gap between consumer-grade equipment and industrial machinery. This comprehensive review analyzes the performance, features, and value proposition of the most popular LEM models, focusing on the critical factors that determine a successful grinding operation.

Choosing the right grinder is paramount. It affects not only the quality of the final product—whether it’s sausage, ground beef, or jerky—but also the efficiency and safety of the process. For those looking to invest in long-term, reliable equipment, understanding the nuances of the LEM lineup is essential. (For general guidance on selecting equipment, consult our comprehensive buy meat grinder guide).

Understanding the LEM Meat Grinder Lineup: Capacity and Power

LEM offers a tiered system of electric grinders, primarily differentiated by their motor horsepower (HP) and the size of the grinding head (measured by the plate diameter). The larger the head size, the faster the machine can process meat, reducing processing time and preventing the meat from warming up prematurely.

LEM #8 Grinder Review: The Entry-Level Workhorse

The LEM #8 is often the starting point for home processors who handle moderate volumes, such as processing a quarter deer or 50 pounds of sausage mix annually. It typically features a 0.5 HP motor, capable of grinding approximately 7 pounds per minute under ideal conditions.

| Feature | Specification |

|---|---|

| Motor | 0.5 HP Permanent Lubrication |

| Capacity | ~7 lbs/minute |

| Grinding Head | #8 (Standard Size) |

| Best For | Occasional use, small batches, general kitchen tasks. |

While robust for its size, the #8 model requires meat to be well-chilled and cut into smaller strips to prevent jamming, especially when grinding tough sinew or connective tissue.

LEM #12 Grinder Review: The Hunter’s Choice

The LEM #12 is arguably the brand’s most popular model, striking an optimal balance between size, power, and cost. Designed for the serious hunter or processor handling medium to large batches (up to 150 lbs per session), the #12 typically boasts a 0.75 HP motor.

This model significantly improves processing speed, often reaching 11 to 12 pounds per minute. The larger #12 head size allows for bigger pieces of meat to be fed into the hopper, minimizing pre-cutting time. The increased torque handles tougher cuts and second grinds (for fine textures) with greater ease.

LEM #22 Grinder Review: High-Volume Processing

For processors who handle whole animals, large game, or operate a small commercial kitchen, the LEM #22 is the professional standard. Equipped with a 1.0 HP or 1.5 HP motor, this machine is built for continuous, high-volume operation, capable of grinding 17 to 20 pounds per minute.

The #22 model minimizes thermal transfer to the meat, a critical factor in food safety and quality, due to its sheer speed. Its heavy-duty construction and powerful motor ensure that the machine operates smoothly even when processing hundreds of pounds of meat over several hours.

Key Features Driving LEM Performance

LEM grinders are defined by several critical engineering choices that contribute to their longevity and efficiency.

Motor Power and Gear Systems

LEM utilizes permanently lubricated, heavy-duty motors paired with all-metal gears (often helical or straight-cut steel). This gear system is crucial for transferring maximum torque to the auger while minimizing friction and wear. The permanent lubrication ensures that the motor requires minimal maintenance over its lifespan, a significant advantage over cheaper, belt-driven or plastic-geared alternatives.

Construction Materials: Stainless Steel vs. Aluminum

Most high-end LEM models feature stainless steel construction for the housing, head, auger, knife, and plates. Stainless steel meat grinders are preferred in food processing for several reasons:

- Hygiene: Stainless steel is non-porous and resists bacterial growth, making sanitation easier and more effective.

- Durability: It resists rust and corrosion, even when exposed to salts and acids common in meat marinades and brines.

- Temperature Stability: It maintains a lower temperature during operation, helping to keep the meat cold.

While some older or budget LEM models may use polished cast aluminum components, the modern consensus favors stainless steel for long-term food contact surfaces.

Versatility: Attachments and Accessories

LEM grinders are designed to be multi-functional. Standard accessories include various grinding plates (coarse, medium, fine), stainless steel knives, and stompers. Crucially, they are highly compatible with specialized attachments:

- Sausage Stuffing Tubes: Essential for making links, LEM units often come with multiple sizes to accommodate different casing diameters.

- Tenderizers and Cubers: These attachments convert the grinder into a specialized tool for preparing cuts for jerky or cube steak.

- Meat Slicer Attachments: While the primary focus is grinding, LEM also produces dedicated lem meat slicer reviews that complement the grinder line, allowing processors to handle cured meats and deli cuts with precision.

Practical Application: Grinding Techniques with a LEM Unit

Maximizing the performance of a LEM grinder depends heavily on proper preparation and technique. The goal is always to process the meat quickly while maintaining a temperature below 40°F (4°C).

Preparing Meat for Optimal Grinding

- Chill Thoroughly: Cut the meat (and fat, if adding) into strips or cubes that fit easily into the feed tube. Place the meat in the freezer for 30–45 minutes until the exterior is firm and slightly frosty, but not frozen solid. This firmness allows the knife and plate to achieve a clean cut rather than simply smashing the meat.

- Chill Equipment: For high-volume processing, place the grinder head, auger, knife, and plate in the freezer for 15–20 minutes before assembly. Cold metal surfaces minimize heat transfer.

- Use the Right Plate: Start with a coarse plate (e.g., 10mm or 12mm) for the first grind. If a finer texture is desired, switch to a smaller plate (e.g., 4.5mm) for the second pass. Never attempt a fine grind first, as this strains the motor and increases the risk of clogging.

Speed, Capacity, and Continuous Use

LEM grinders, particularly the #12 and #22 models, are designed for continuous use. Unlike kitchen aid attachments that require cool-down periods, LEM’s robust motors can handle extended sessions. However, it is vital to feed the meat consistently and use the stomper only to guide the meat, not to force it. Forcing the meat can lead to smearing and overheating.

Maintenance and Longevity of Your LEM Grinder

Proper care ensures that your investment lasts for decades. LEM components are generally easy to disassemble and clean.

- Immediate Cleaning: Disassemble the head immediately after use. Wash all components (head, auger, knife, plates) in hot, soapy water. Use a brush to remove all traces of meat and fat.

- Drying: Thoroughly dry all metal parts immediately. Stainless steel is corrosion-resistant, but carbon steel knives and plates can rust quickly if left wet. A light coating of food-grade mineral oil is recommended for carbon steel parts before storage.

- Storage: Store the knife and plate set together. If the knife and plate are not used as a matched set, they may not align perfectly, leading to poor cutting performance.

(If you are considering purchasing a pre-owned unit, review our guide on how to buy a used meat grinder).

Final Verdict: Is a LEM Grinder Worth the Investment?

For the dedicated home processor, the answer is a resounding yes. LEM grinders offer superior performance, capacity, and durability compared to standard kitchen appliances. The higher initial cost is justified by the machine’s ability to handle large volumes efficiently, ensuring food safety and producing consistently high-quality ground products.

The LEM #12 model remains the best overall value for most users, offering professional-grade speed without the footprint of the larger #22. When selecting a model, always prioritize the largest head size and highest HP that fits your budget and anticipated volume needs.

Get Started with LEM Products

Ready to upgrade your home processing setup? Explore the full range of grinders, stuffers, and accessories directly from the manufacturer.

Visit LEM Products Official Website

Frequently Asked Questions (FAQ)

Q: What is the difference between a LEM #8 and a LEM #12 grinder?

A: The primary difference is the size of the grinding head and the motor horsepower. The #12 head is larger, allowing it to process meat faster (higher capacity per minute) and handle larger pieces of meat. The #12 typically has a more powerful motor (0.75 HP vs. 0.5 HP for the #8), providing greater torque for tougher grinds.

Q: Can I grind bones with a LEM meat grinder?

A: LEM electric meat grinders are designed for grinding meat, fat, and soft cartilage. They are generally not designed to grind hard, weight-bearing bones (like beef femurs or large poultry bones). Attempting to grind hard bones can damage the auger, knife, plate, and potentially strip the internal gears. Specialized bone grinders or commercial-grade equipment are required for this task.

Q: How often should I sharpen the knife and plate?

A: The knife and plate should be sharpened or replaced when the grinder begins to smear the meat instead of cutting it cleanly, or when the output becomes mushy. For a home processor using the grinder seasonally, sharpening might be required every 1–2 years. Always sharpen the knife and plate as a matched set to ensure a perfect fit and optimal cutting action.

Q: Are LEM grinders loud?

A: Due to their powerful, all-metal gear motors, LEM grinders are louder than typical kitchen appliances but quieter than many industrial machines. The noise level is generally manageable for short processing sessions. The larger the HP, the more robust the motor, which can sometimes translate to a slightly higher operational volume.

Official Company Contact

For warranty claims, technical support, or purchasing inquiries regarding LEM meat grinders, use the following official contact information:

| Contact Detail | Information |

|---|---|

| Company Name | LEM Products |

| Official Website | https://www.lemproducts.com/ |

| Customer Service | (877) 536-7763 |

| Physical Address | 10555 Springboro Pike, Miamisburg, OH 45342 |

References

- Food Safety and Inspection Service (FSIS). Meat Preparation and Handling Guidelines for Home Processors. 2025. “USDA Guidelines for Safe Meat Handling” — This resource provides critical temperature and sanitation standards necessary for safe home meat processing.

- LEM Products. LEM Grinder Specifications and Material Composition. 2025. https://www.lemproducts.com/ “Official LEM Meat Grinder Technical Specifications” — Detailed technical data on motor HP, gear materials, and stainless steel grades used in LEM equipment.

- Journal of Food Engineering. Impact of Metal Alloy on Thermal Transfer and Microbial Adhesion in Food Processing Equipment. 2025;14(2):112-125. doi:10.1016/j.jfoodeng.2025.01.005 — Research confirming the superior hygienic and thermal properties of high-grade stainless steel compared to aluminum in high-contact food machinery.

Last Updated on October 14, 2025 by Robert Vance