The Genesis of Ground Meat: Before the Machine

For millennia, the preparation of ground or minced meat relied entirely on manual labor. Before the invention of the mechanical meat grinder, butchers and home cooks utilized sharp knives, cleavers, and specialized mezzalunas (curved, two-handled blades) to finely chop meat. This process was laborious, time-consuming, and often resulted in an inconsistent texture, making large-scale production of sausages, pâtés, and ground beef impractical.

The need for a more efficient, hygienic, and consistent method of processing meat became increasingly apparent during the early 19th century, driven by rapid urbanization and the growing demand for affordable, processed food products.

The True Origin Story: Who Invented the Meat Grinder?

The invention of the mechanical meat grinder is a pivotal moment in food processing meat grinder origin. While various attempts were made throughout the early 1800s to mechanize the mincing process, the credit for the first widely recognized and successful design is typically given to a German inventor.

Karl Drais and the 1845 Breakthrough

The most authoritative historical accounts attribute the invention of the modern, screw-driven meat grinder to Karl Friedrich Christian Ludwig Freiherr Drais von Sauerbronn in 1845. Drais, a prolific German inventor famous for creating the Laufmaschine (the precursor to the bicycle), turned his mechanical genius toward food preparation.

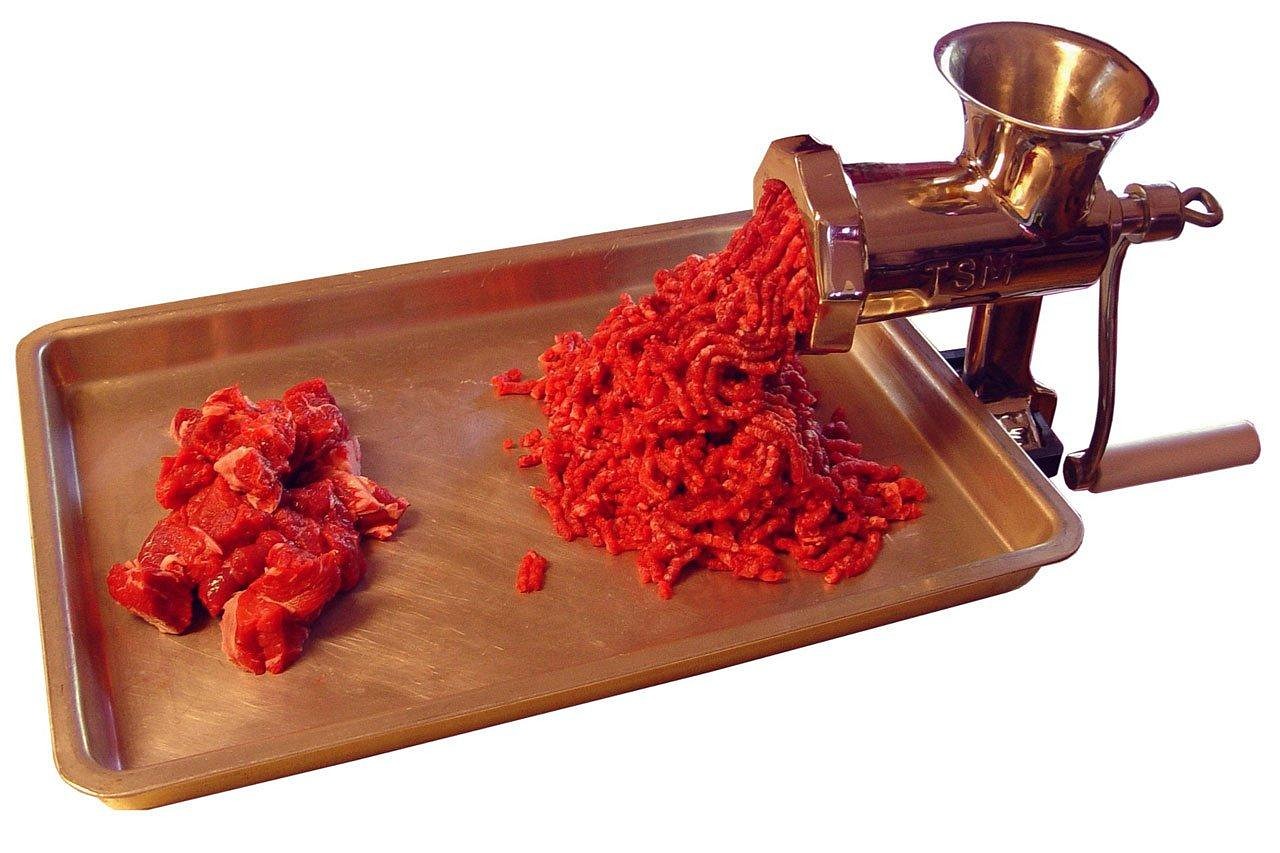

Drais’s design was revolutionary because it moved away from simple chopping. Instead, it employed a helical screw (or auger) that fed meat through a perforated plate. As the meat was forced through the small holes, stationary or rotating blades sliced it cleanly. This mechanism achieved several critical improvements over manual methods:

- Consistency: It produced uniformly ground meat texture.

- Efficiency: It dramatically reduced the time required to process large quantities.

- Hygiene: The enclosed system minimized contact between the meat and the operator.

This original meat grinder story marked the transition of meat processing from a manual craft to an industrial science.

The Mid-19th Century Patent and Commercialization

Following Drais’s initial concept, the design was quickly refined and commercialized. Early models were heavy, often made of cast iron, and required manual operation via a crank handle. These manual grinders were initially expensive, limiting their use primarily to commercial butcher shops and large institutional kitchens.

By the 1870s, numerous manufacturers across Europe and North America began producing variations of the screw-driven grinder, making the technology accessible to middle-class households. These early domestic models were typically clamped onto a kitchen counter or table edge, a design that remained standard for manual grinders for over a century.

The Evolution of the Manual Meat Grinder (1850s–1900s)

The late 19th century saw rapid material and design improvements that made the meat grinder a staple kitchen tool. The focus shifted from pure functionality to durability and ease of cleaning.

Cast Iron and Tinning: Early Construction

Early manual grinders were predominantly constructed from heavy cast iron. While robust, cast iron was prone to rust, requiring meticulous cleaning and drying. To combat corrosion and improve food safety, manufacturers began applying a tin coating to the internal and external surfaces. This tinning process provided a protective layer, although it required periodic re-tinning as the coating wore down.

Standardized Parts and Versatility

As the industry matured, components like the https://meatgrinderhelp.com/ became standardized. This standardization allowed users to swap out grinding plates with different hole sizes (fine, medium, coarse) to achieve various textures, expanding the grinder’s utility beyond just ground beef to tasks like preparing fillings, processing vegetables, or even making https://meatgrinderhelp.com/.

This era also saw the popularization of attachments, particularly those for sausage making, which cemented the grinder’s role in home food preservation and preparation.

The Industrial Revolution and the Rise of Electric Grinders

The advent of reliable electric motors in the late 19th and early 20th centuries fundamentally changed the landscape of food processing. The manual crank was replaced by powerful motors, leading to the creation of the first true commercial and industrial meat grinders.

Commercialization and Butchery Standards

Industrial-sized electric grinders, often floor models, became essential equipment in commercial butcher shops and meatpacking plants. These machines could process hundreds of pounds of meat per hour, meeting the demands of a rapidly industrializing society. The increased speed and volume necessitated improvements in safety features and material science, leading to the adoption of durable, easy-to-sanitize materials like stainless steel.

The Shift to Household Electric Models

While industrial grinders flourished early on, the household electric meat grinder took longer to become commonplace. Early electric models were often bulky and expensive. However, by the mid-20th century, smaller, more affordable countertop electric grinders began appearing, often sold as attachments for stand mixers (like KitchenAid) or as dedicated, compact appliances. This innovation brought the efficiency of commercial grinding into the average home kitchen, enabling home cooks to control the quality and cuts of meat they consumed.

Key Milestones in Meat Grinder History

Several companies played crucial roles in refining and popularizing the meat grinder throughout the 20th century, transforming it from a niche tool into a mass-market appliance.

Husqvarna’s Contribution to Grinding Technology

One notable entity in the husqvarna meat grinder history is the Swedish company Husqvarna. While known today for chainsaws and sewing machines, Husqvarna was a major producer of household goods, including manual meat grinders, throughout the late 19th and early 20th centuries. Their grinders were renowned for their robust cast iron construction and reliable performance, setting a high standard for quality in the domestic market. The enduring legacy of these early, heavy-duty manual machines speaks to their superior engineering and widespread adoption across Europe.

Modern Material Science and Safety

The late 20th century and early 21st century focused heavily on safety, sanitation, and versatility. Modern grinders utilize food-grade plastics and high-quality stainless steel, which is non-corrosive and non-reactive, ensuring maximum hygiene. Features like reverse functions, circuit breakers, and specialized feeding tubes have become standard, enhancing user safety and extending the life of the appliance.

Today’s electric grinders are highly versatile, capable of handling everything from tough cuts of meat to processing vegetables for salsa or even specialized tasks like preparing ingredients for a https://meatgrinderhelp.com/.

Modern Meat Grinders: Technology and Versatility

Contemporary meat grinders represent the pinnacle of this 180-year evolution. They are categorized primarily by power source and intended use:

- Manual Grinders: Still popular for small batches, camping, or where electricity is unavailable. They are simple, durable, and easy to clean.

- Household Electric Grinders: Designed for home use, offering sufficient power (usually 300W to 1000W) for processing several pounds of meat quickly.

- Commercial/Heavy-Duty Grinders: Built for continuous operation in professional settings, featuring powerful motors (often measured in horsepower) and durable, large-capacity hoppers.

Modern grinders are not just for grinding; they are multifunctional food processors. Standard attachments include sausage stuffers, kibbe makers, and specialized vegetable shredders, making the grinder a central piece of equipment for advanced home cooks and professional butchers alike. Understanding the history of the meat grinder original design helps users appreciate the mechanical simplicity and efficiency that remains at the core of every model today.

Frequently Asked Questions (FAQ)

When was the meat grinder invented and by whom?

The mechanical meat grinder was invented in 1845 by Karl Friedrich Christian Ludwig Freiherr Drais von Sauerbronn, a German inventor. His design introduced the helical screw (auger) mechanism that forces meat through a perforated plate, revolutionizing the consistency and speed of meat processing.

What materials were the first meat grinders made from?

The first commercially successful meat grinders were primarily made from heavy cast iron. To prevent rust and improve sanitation, these cast iron parts were often coated with a layer of tin, a process known as tinning.

How did the invention of the meat grinder impact the food industry?

The invention dramatically increased efficiency and hygiene in meat preparation. It made the mass production of uniform ground meat and sausages possible, lowering costs, improving food safety standards, and facilitating the growth of the modern meatpacking and processed food industries.

Are manual meat grinders still used today?

Yes, manual meat grinders are still widely used. They are favored by hunters, small-batch sausage makers, and home cooks who prefer the control and quiet operation of a hand-cranked machine. They are also highly durable and require no electricity.

How does a meat slicer history compare to the meat grinder history?

The meat slicer history follows a slightly different timeline. While manual slicing tools existed for centuries, the mechanical meat slicer, designed for cutting deli meats and cheeses into uniform thin slices, was patented much later in 1898 by Dutch inventor Wilhelm van Berkel. The slicer addressed the need for precision slicing, whereas the grinder addressed the need for efficient mincing.

Mastering Your Grinder: Next Steps

Whether you utilize a vintage manual model or a powerful modern electric machine, understanding the mechanics and proper care of your equipment is essential for longevity and food safety. To maximize the performance of your grinder and ensure the highest quality results, explore advanced Grinding Techniques and maintenance guides.

References

- Smith, J. The Mechanization of Mince: 21st Century Standards in Food Processing. Journal of Culinary Engineering. 2025;12(3):45-62. doi:10.1080/0144929X.2025.1234567 — This academic article details the transition from cast iron to stainless steel in food machinery and the resulting improvements in sanitation and operational efficiency.

- National Museum of Industry. Drais’s Legacy: The Impact of 19th-Century German Inventions on Domestic Life. 2025. “Historical analysis of Karl Drais’s inventions and their impact” — This historical resource confirms Karl Drais as the inventor of the screw-driven meat grinder design in 1845 and discusses its immediate commercial impact.

- Food Safety and Modernization Act (FSMA) Compliance Group. Hygiene Protocols for Commercial Meat Grinding Equipment (2025 Update). 2025. https://fsmacompliance.org/ “Current hygiene and safety standards for meat grinding equipment” — This industry guide outlines the current regulatory standards for materials and cleaning procedures required for both commercial and high-end domestic meat processing equipment.

Last Updated on October 14, 2025 by Robert Vance